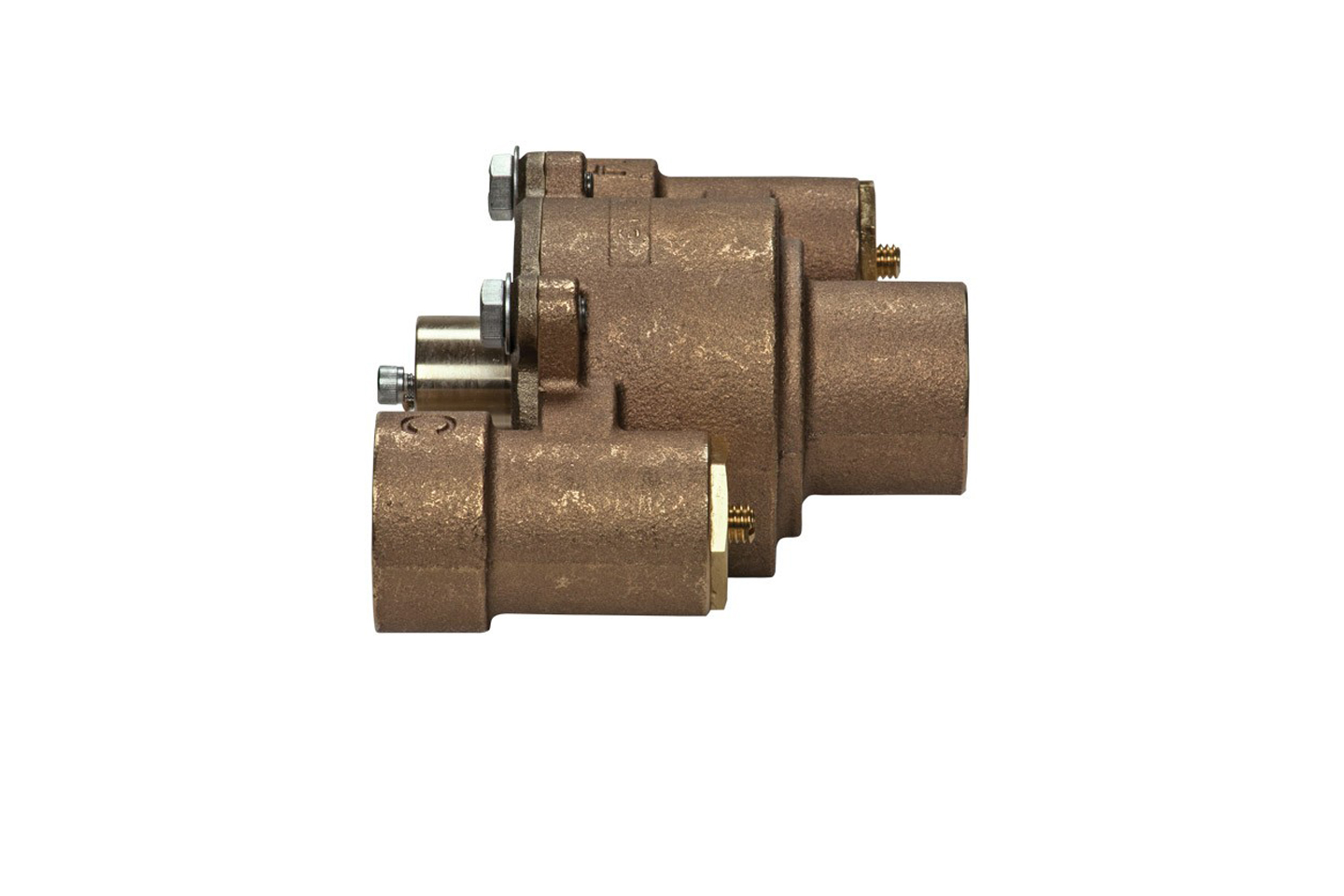

Description

Model 9201E emergency mixing valve (patent pending) thermostatically mixes hot and cold water to provide a safe fluid supply for emergency showers and eyewash equipment. Additionally, to ensure a fail-safe water supply for emergency shower and eyewash stations, a series of cold water by-pass valves open in the event of hot water pressure loss. (No gauges supplied – ASSE 1071 standard recommends gauges be placed 5 to 8 feet (1.52 to 2.44 m) downstream for the most accurate temperature measurement.)

- A flow rate of 1 to 31 gpm (3.8 to 117.3 L) for better temperature control across the operating range

- AXION’s superior design and technology provide a complete safety solution for increased victim comfort.

- Lowest internal pressure drop for this class of valve (advantage where supply pressure is low)

- Wax based thermostat technology for fast response time with proven highly reliable temperature control

- Highest Cold Water Bypass flow rate in the industry (65% of rated tepid flow rate)

- Modular brass design with internal check stops

- Over-sized valve seats resist failures caused by foreign matter

- A new and efficient shuttle design eliminates valve sticking

- A custom funnel design improves temperature control at low flow rates

- Outlet temperature is factory set to 85® F (29® C).

- Tempered water: High temperature limit is factory set to 90® F (32® C).

- Cold water by-pass valves are closed during normal operation, regardless of flow rate.